Biosensing of Bacterial Secretions via Topological Defects at Smectic Interfaces

Characterizing the anchoring properties of smectic liquid crystals (LCs) in contact with bacterial solutions is crucial for developing biosensing platforms. In this study, we investigate the anchoring properties of a smectic LC when exposed to Bacillus subtilis and Escherichia coli bacterial suspensions using interfaces with known anchoring properties. By monitoring the optical response of the smectic film, we successfully distinguish different types of bacteria, leveraging the distinct changes in the LC’s response. Through a comprehensive analysis of the interactions between bacterial proteins and the smectic interface, we elucidate the potential underlying mechanisms responsible for these optical changes. Additionally, we introduce the utilization of topological defects, the focal conic domains (FCDs), at the smectic interface as an indicative measure of the bacterial concentration. Our findings contribute to the understanding of bacteria–LC interactions and demonstrate the significant potential of smectic LCs and their defects for biosensing applications, paving the way for advancements in pathogen detection and protein-based sensing.

Properties of 2D smectic liquid crystal foams

As a two-phase system, foams are widely applied in the industry and exist ubiquitously in our daily lives. For this reason, studying them and investigating the parameters that affect their properties is crucial for the development of new and improved foam-based products. In this project, we create 2D foam using an ordered fluid, the smectic liquid crystal (LC), and discuss the experimental parameters that affect their fabrication, including temperature and confining conditions. Then, we examine the influence of the injected airflow rate and drainage on their structure, size, liquid fraction, and stability. Finally, we compare their behavior to that of low-viscosity liquid foams and discuss the difference between them. Our findings indicate that surface tension is the dominant parameter in LC foam systems. Despite the strong elasticity of LCs, surface tension plays a crucial role in determining the properties of elastic foams. These results provide valuable insights that can be applied to different industrial applications. For instance, they may find relevance in the fields of cosmetics, thermal insulation, oil recovery, and sensing, where the fabrication of foams with high-viscosity fluids is required.

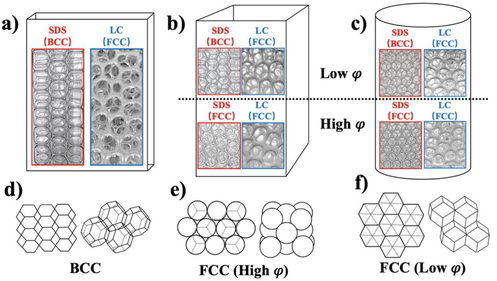

Geometric confinement of 3D smectic liquid crystal foams

Due to their long history and extensive applications within modern society, foams have always been a popular topic of study. These systems are present everywhere in our life. They are also valuable in many industrial applications. For this reason, it is essential to continue investigating their properties and develop new materials to fabricate them. In this project, we demonstrate a new way to create 3D foams by using an ordered viscoelastic material, the smectic liquid crystal (LC). Because of their lamellar structure, which is similar to soap, and their tunable properties that can be controlled via geometric confinement and external fields, smectic LCs are suitable for the fabrication of bubbles and foams. We present a compelling study of the parameters that influence the fabrication of LC foams in 3D. Particularly, we analyze the effects of the airflow rate and the geometry of confining boundaries on the assembly of their cells. This work paves the way to exploiting new materials to fabricate foams with better monodispersity, uniformity, and controlled ordering that are useful in a wide range of industrial applications for which the tuning of properties is required. This includes the fields of oil recovery, decontamination, architecture, and design.

Assembly of smectic defects at undulated surfaces

The assembly of topological defects in liquid crystals has drawn significant interest in the last decade due to their ability to trap colloidal objects and direct their arrangements. They have also brought about a high impact in modern technologies, in particular in optics, e.g., microlens arrays, soft lithography templates, and optically selective masks. Here we study the formation of defects in smectic A liquid crystal with hybrid texture at undulated surfaces. We investigate the role of surface topography on the organization of focal conic domains (FCDs) in smectic films. We demonstrate new methods for assembling FCDs and disclinations into hierarchical structures. When the liquid crystal is heated to the nematic phase, we observe stable defect lines forming at specific locations. These defects are created to satisfy anchoring conditions and the geometry of confinement imposed by the boundaries. Once the liquid crystal is cooled to the smectic A phase, the disclinations maintain their positions, but periodic structures of reversible FCDs facing opposite directions arise between them. We report the correlation between the size of these FCDs and their eccentricities with the morphology of the interface. This work paves the way for creating new procedures to control the assembly of functional nanomaterials into tunable assemblies that may find relevance in the field of energy technology including in optoelectronic and photonic applications.

Elastocapillary effects at free-standing smectic films

Colloidal particles at complex fluid interfaces and within films assemble to form ordered structures with high degrees of symmetry via interactions that include capillarity, elasticity, and other fields like electrostatic charge. Here we study microparticle interactions within free-standing smectic-A films, in which the elasticity arising from the director field distortion and capillary interactions arising from interface deformation compete to direct the assembly of motile particles. New colloidal assemblies and patterns, ranging from 1D chains to 2D aggregates, sensitive to the initial wetting conditions of particles at the smectic film, are explored. This work paves the way to exploiting LC interfaces as a means to direct spontaneously formed, reconfigurable, and optically active materials.

Au nanoparticles in blue phase LCs: Towards "soft" nanocrystals

Blue phases (BPs), a distinct class of liquid crystals (LCs) with 3D periodic ordering of double twist cylinders involving orthogonal helical director twists, have been theoretically studied as potential templates for tunable colloidal crystals. In this project, we explore the spontaneous formation of thermally reversible, cubic crystal nanoparticle (NP) assemblies in BPs. The NPs assemble by selectively migrating to periodic strong trapping sites in the BP disclination lines. This presents an interesting opportunity to develop novel dynamic optical materials.

Gardens of smectic flowers: Towards "smart" microlenses

A self-assembly of microlenses on a curved interface can be obtained by pinning smectic liquid crystals around a micropillar with appropriate boundary conditions. This hierarchical structure of microlenses, with variable focal lengths from a few micrometers to a few tens of micrometers, is similar to an insect's compound eye; the lenses are reconfigurable with temperature and sensitive to light polarization.

Effect of the light polarization on the smectic lenses.

Effect of the temperature on the smectic lenses.

Migration of particles at curved nematic interfaces

In this research, we develop new means of directing colloids at an interface to assemble into complex configurations by exploiting defects in a liquid crystal (LC). Through confinement of a nematic LC over a topographically patterned surface, we demonstrate the formation of defects at precise locations in the LC bulk. These defects source elastic distortion fields that guide the assembly of colloids constrained to the LC–air interface.

Creation of a defect loop around a micropost in an oriented nematic liquid crystal.

The defect created in bulk, can be used to direct assembly of particles at the interface.

Assembly of anisotropic particles in oriented nematic liquid crystals

Microbullet particles, cylinders with one blunt and one spherical end, offer a novel platform to study the effects of anisotropy and curvature on colloidal assembly in complex fluids. Here, we disperse microbullets in 5CB nematic liquid crystal (NLC) cells and form oriented elastic dipoles with a nematic point defect located near the curved end. This feature allows us to study particle interactions as a function of dipole alignment. By careful control of the surface anchoring at the particle surface and the confining boundaries, we study the interactions and assembly of microbullets under various conditions.

When microbullets with homeotropic surface anchoring are dispersed in a planar cell, parallel dipoles form linear chains parallel to the director, while antiparallel dipoles orient side-to-side.

In a homeotropic cell, particles rotate to orient their long axis parallel to the director. When so aligned, parallel dipoles repel and form 2D ordered assemblies with hexagonal symmetry that ripen over time owing to attraction between antiparallel neighbors.

The anchoring conditions inside the cell can be altered by application of an electrical field, allowing us to flip microbullets to orient parallel to the director, an effect driven by an elastic torque.

Confinement of liquid crystals into spherical geometries

A nematic coating could be used to create a valency for spherical colloidal particles through the functionalization of nematic topological defects. Experimental realizations however question the complex behaviour of solid particles and defects embedded in such a nematic spherical shell. In order to address the related topological and geometrical issues, we have studied micrometer-sized silica beads trapped in nematic shells. We show how the coupling between capillarity and nematic elasticity offers new ways to control the valence and directionality of shells.

Dripping mode: nematic double emulsions

Jetting mode: nematic double emulsions

Assembly of spherical particles at an air/nematic interface

We examine the behavior of spherical silica particles trapped at an air–nematic liquid crystal interface. When a strong normal anchoring is imposed, the beads spontaneously form various structures depending on their area density and the nematic thickness. Using optical tweezers, we determine the pair potential and explain the formation of these patterns.

Particles form hexagonal structures at an air-nematic interface with homeotropic anchoring.

Particles at a thin air-nematic interface form linear chains along the easy axis of the nematic film.

Disclinations in nematics are high trapping cites for colloidal particles.